How to Scale Serial Production & Strengthen Supply Chains

Streamline serial production and mitigate supply chain risks with MakerVerse’s expert solutions.

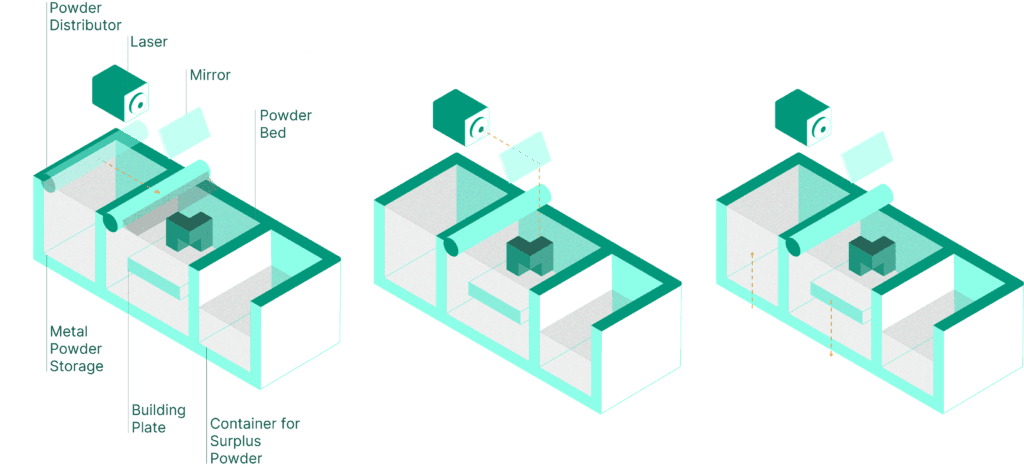

Laser powder bed fusion (LPBF) is the leading additive manufacturing technology for metals. In the LPBF process, a high-powered laser selectively melts and fuses metal powder to form each layer of the part.

The laser selectively melts specific regions of the powder bed according to the digital design, enabling precise control over the part’s geometry. As the process builds the part layer by layer, the laser is used to fuse layers, allowing for the creation of intricate internal features and complex geometries.

Laser Powder Bed Fusion (LPBF) is also known as Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS). This technology requires an inert gas atmosphere and a laser to melt metal powder which is stored in a powder bed.

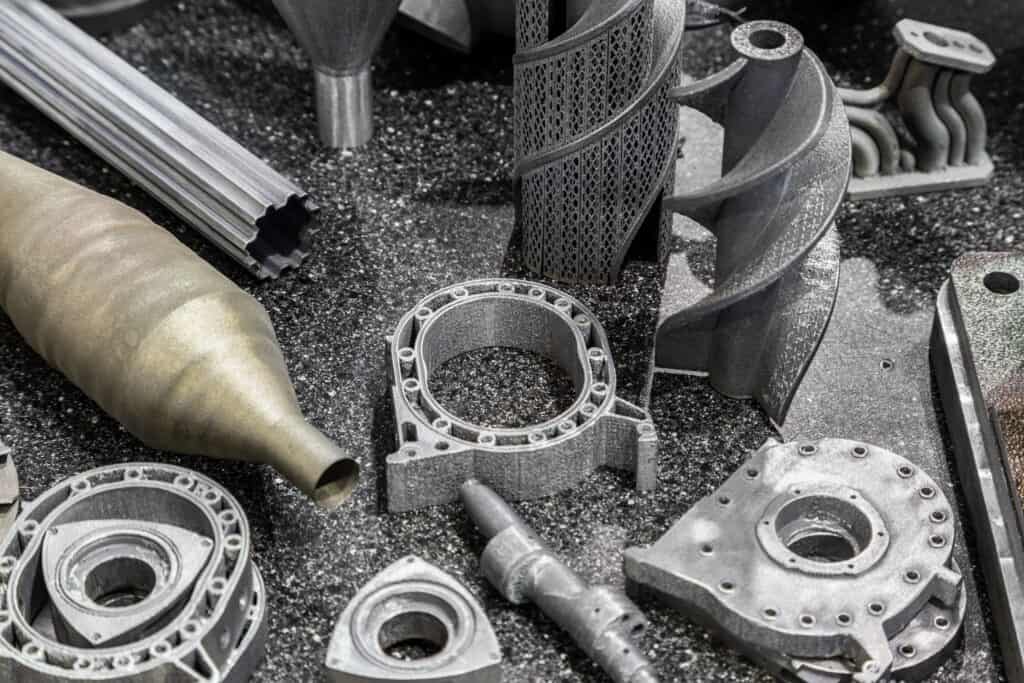

Compared to other additive manufacturing technologies, LPBF offers superior resolution and material properties for metal parts. Unlike traditional manufacturing methods such as injection molding, which require expensive tooling and are limited in producing complex shapes, LPBF enables rapid turnaround and the fabrication of highly intricate, lightweight components without the constraints of molds or dies.

As this happens repetitively layer by layer on the build platform, the material fuses together to form the part.

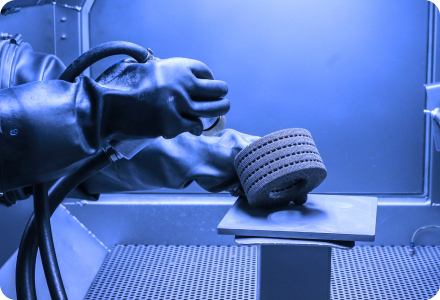

With the help of support structures, LPBF enables complex geometries that are not achievable through subtractive manufacturing methods. Furthermore, this additive manufacturing process requires no additional tooling, making it a cost-efficient manufacturing technology. Another advantage of powder bed technologies is the recyclability of unused powder.

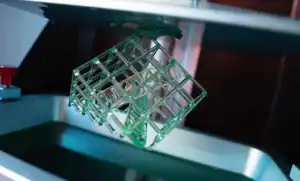

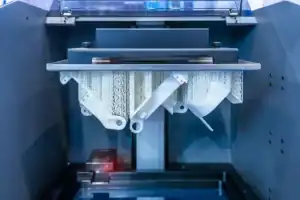

The process uses a high-precision laser to selectively melt and fuse metal powder, building parts layer by layer. It begins with the application of a thin layer of powder onto the build platform inside a controlled build chamber. The laser then melts the powder according to the digital design. After each layer is completed, the platform lowers and a new powder layer is spread.

This cycle repeats until the part is fully formed, enabling the creation of intricate geometries with excellent mechanical properties. Thanks to this precision and detail, LPBF is ideal for producing functional prototypes and high-performance end-use parts—without the need for traditional tooling.

Support structures are used as needed, allowing for overhangs and complex features that are not possible with subtractive methods. Process parameters like laser power, scan speed, and energy density are fine-tuned to ensure part quality and optimal microstructure.

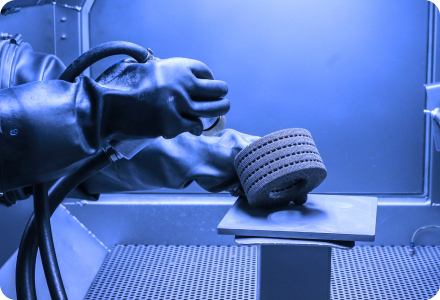

Another advantage of LPBF is powder efficiency: unused powder can be sieved and reused, reducing material waste. Each print job is carefully monitored throughout the process to ensure dimensional accuracy and part integrity.

As the leading metal additive manufacturing technology, LPBF is used by many industries on the MakerVerse platform, including automotive, energy, and others. LPBF is often integrated into the overall production process, enabling seamless transition from design to finished part. It plays a crucial role within broader production and manufacturing processes, supporting efficient workflows and achieving high-quality outcomes. LPBF is also one of several additive manufacturing processes available for producing metal parts, offering unique advantages in precision and complexity.

This technology is equally suitable for producing functional prototypes as engineered end-use parts, thanks to the wide range of material options and various metals—such as titanium, aluminum, stainless steel, superalloys, and cobalt-chromium—that can be used with LPBF.

Looking for bigger parts? You’re in the right place.

While the standard size for LPBF parts is typically 500 mm in the longest dimension, we offer state-of-the-art LPBF printers capable of up to 1.5 meters in the longest dimension. With these capabilities, you can explore all-new applications in prototyping, spare parts, and series production.

Learn how to go far beyond the standard sizes typically available

Vice President of Additive Manufacturing at Siemens Energy

MakerVerse give you the flexibility to source parts however you need. Get instant quotes and quickly order parts with on-demand manufacturing. For sophisticated orders, our team of experts will work with you to develop, align and supervise a manufacturing quality plan from start to finish.

LPBF technology supports a diverse range of metal powders, including titanium, aluminum, stainless steel, and cobalt chrome, each offering unique advantages for different industrial applications. The mechanical properties of LPBF-processed parts are determined by several factors, such as the chemical composition of the powder material, the size and distribution of powder particles, and the specific processing parameters used during manufacturing.

Typical powder particles for LPBF have a particle size between 10 and 100 micrometers, and the layer thickness can be adjusted from 10 to 200 micrometers to balance surface quality and build speed. Critical parameters like energy density, scanning speed, and powder layer thickness directly influence the microstructure, density, and corrosion resistance of the final part. LPBF-processed components are known for their high density and excellent mechanical properties, making them suitable for demanding environments such as aerospace, automotive, and medical implants. Support structures are often required during the manufacturing process to stabilize parts and ensure proper adhesion to the build plate, especially when producing complex geometries. By carefully controlling these variables, LPBF delivers parts with superior surface quality and performance, tailored to the needs of advanced industrial applications.

Use our interactive technology and material advisor to find out.

Streamline serial production and mitigate supply chain risks with MakerVerse’s expert solutions.

Discover strategies to ensure color uniformity in FDM 3D printing, enhancing the aesthetic and functional quality of your parts.

Compare CNC and metal 3D printing costs side by side with MakerVerse’s instant quoting tools.

Learn all the terminology in additive manufacturing, from A to Z-Offset.