Multi Jet Fusion vs Selective Laser Sintering

What are the advantages and disadvantages of Multi-Jet Fusion (MJF) and Selective Laser Sintering (SLS)? You’re not alone in wondering; the reasons for using one over the other aren’t always obvious.

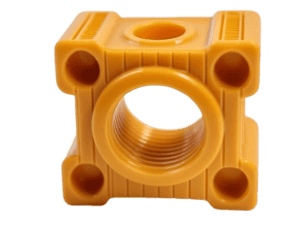

Both additive manufacturing technologies create highly complex and reliable components from polymers. They’re affordable and reliable methods for making everything from functional prototypes to end-use parts. However, critical differences in each technology’s capabilities can significantly impact your 3D printing project. This guide will show you which technologies are best suited for your project.How the MJF and SLS Technologies Work

SLS and MJF are powder bed fusion technologies that build up parts layer by layer. As a foundational step in both technologies, a thin layer of powder is spread over the build platform. As the name suggests, SLS uses a laser to heat the powder and fuse the layers. MJF is a newer technology developed by HP. It uses heating lamps, fusing agents, and chemical agents to fuse and detail the layers. Between these technologies, there are differences in what’s possible regarding the size, powders, finishes, and, most importantly, the best use cases.The SLS Printing Process

The MJF Printing Process

Start Your Manufacturing Project with MakerVerse

MakerVerse is a platform for sourcing industrial parts. It provides instant access to a vetted supply chain and a full range of manufacturing technologies. With AI-powered quoting, order management, and fulfilment, MakerVerse helps with everything from initial prototypes to full-scale production.

MJF and SLS Powders

One of the main differences between SLS and MJF is the range of powder material available.

Powder bed fusion technology, including Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF), plays a significant role in producing parts rapidly and efficiently. Both can make parts with the standard thermoplastic polymers, PA 11 and PA 12. These polymers are popular for a good reason: They’re strong, malleable, and biocompatible, and they’re also relatively affordable.

However, SLS offers more powders that aren’t available in MJF. Some of these include:

PA 12 Aluminum Filled: The aluminum filling gives the component a metallic appearance. It also provides excellent dimensional stability at high temperatures while maintaining the light weight of a polymer. Thus, it’s ideal for components operating in high temperatures or under great stress.

PA 12 Flame Retardant: This is suitable for parts requiring flame retardancy for safety or regulatory reasons (such as in the aerospace and rail industries).

PEEK: Polyetheretherketone is a high-performance polymer capable of withstanding high temperatures and harsh environments.

Part Quality and Performance

![]()

SLS and MJF technologies are known for producing high-quality parts with excellent mechanical properties.

SLS parts are renowned for their robust mechanical properties, although they tend to exhibit anisotropic behavior, meaning their strength can vary depending on the direction of the applied load.

In contrast, MJF parts are characterized by their consistent mechanical properties due to their more isotropic nature, ensuring uniform strength and durability in all directions. The surface finish of both SLS and MJF parts is typically rough and matte. However, this can be significantly improved through post-processing techniques such as bead blasting and media tumbling.

Finish

So, how do the parts look when printing is finished? SLS parts are printed in white, making them easier to color, or sometimes gray. MJF prints in dark gray.

A white part printed by SLS vs. the dark gray of a part created with MJF.

Due to the printed components’ limited colors and grainy finish, the following post-processing options are popular for both SLS and MJF.

Media Blasting: An abrasive medium (sand or glass beads) is applied at high pressure. This process removes the remaining powder. It also helps achieve the desired surface roughness and polishes the surface.

Painting: A professional spray-painting system can add additional colors. Various colors are available, but artwork can be intricate with complex geometries.

Dyeing: The color is changed by submerging the part in water mixed with dye. This process is ideal for parts with complex geometries, as the dye can easily reach the entire surface area.

Smoothing: A chemical reaction results in a very smooth surface.

Tumbling: The parts are placed in a rotating container. They’re then deburred, finely ground, and polished.

You can read this guide for more information about SLS post-processing options.

Cost and Lead Time Considerations

The cost of producing SLS and MJF parts is influenced by several factors, including the material used, part complexity, and production volume. Generally, SLS is more cost-effective for smaller production volumes, while MJF becomes more economical at larger scales. The lead time for both technologies is relatively fast, although SLS typically takes longer due to the laser scanning process.

MJF, with its faster cooling time and higher powder reuse rate, offers a more efficient option for high-volume production, making it a preferred choice for large-scale manufacturing.

Design Considerations and Limitations

When designing parts for SLS and MJF, it is essential to consider the specific limitations of each technology. Both require a minimum wall thickness and feature size to ensure successful printing.

SLS parts can be prone to warping, especially when printing large, flat areas, affecting the final part’s accuracy. MJF parts, on the other hand, may experience shrinkage due to the material’s thermal expansion.

Designers must also account for the support structures required for each technology and the post-processing techniques needed to achieve the desired surface finish.

When to Use MJF vs. SLS

MJF and SLS are useful additive manufacturing technologies that can help you create everything from functional prototypes to end-use parts.

Depending on your use case or needs, it makes sense to choose one technology over the other in the following cases. Compared to traditional manufacturing methods like injection molding, MJF and SLS offer unique advantages in handling complex geometries and mechanical properties.

More Economical Parts: MJF

For larger batches, MJF usually has a price advantage. The printing process is fast, and unused powders are easily recycled, so costs are typically lower than those of SLS. However, SLS systems are open to a wider variety of powders, resulting in potential cost savings depending on which powder is used.

Voluminous Parts: SLS

Selective laser sintering can produce thicker parts than MJF. If this is essential to the form and functionality of your part, then SLS has the advantage. Direct metal laser sintering (DMLS) is another additive manufacturing technology that offers similar benefits for metal parts.

Higher Detail: MJF

Multi Jet Fusion can produce parts with higher levels of detail and higher resolution (1200 dpi). However, SLS offers slightly higher dimensional accuracy. Using PA 12, SLS provides a dimensional accuracy of .03% for parts above 100 mm. MJF offers .05% in comparison.

More significant Parts: SLS

SLS printers can build parts that are more significant than 400 cm. With SLS, the maximum height can reach 605 mm compared to 380 for MJF.

For Advanced Materials: SLS

If your part requires powders other than standard polymers, SLS offers a more excellent selection, including flame-retardant powders with higher performance.

For Colors: SLS

SLS prints in white compared to dark gray. This blank slate makes SLS ideal for the dyeing post-production process, with more color options.