Quality Control Options for CNC Machined Parts

CNC machining is known for its precision. But what’s the best way to test that precision?

Every part produced with MakerVerse undergoes a visual inspection by one of our engineering experts. We also offer a range of optional dimensional, surface, and material property-related inspection reports and certificates. These provide different levels of insight that might be invaluable to understanding how your part will perform and how it was manufactured.

This guide will explain each choice and when they’re best suited for your part.

What is Quality Control in CNC Machining?

Quality control in CNC machining is a systematic process that ensures every part and component meets stringent industry standards and regulations.

This process involves a series of meticulous inspections, tests, and evaluations aimed at detecting any deviations or errors in the manufacturing process. The primary goal of quality control in CNC machining is to identify and address potential issues early on, thereby minimizing the risk of producing defective parts and ensuring customer satisfaction.

Implementing a robust quality control process is crucial for several reasons:

Improved Product Quality and Reliability: Manufacturers can produce parts that meet or exceed quality expectations by consistently monitoring and controlling the manufacturing process.

Reduced Production Costs and Waste: Early detection of errors helps in reducing material waste and rework, leading to cost savings.

Increased Customer Satisfaction and Loyalty: High-quality products lead to satisfied customers who are more likely to return and recommend the manufacturer.

Enhanced Brand Reputation and Competitiveness: Consistently delivering quality products helps build a strong brand reputation and stay competitive in the market.

Compliance with Industry Standards and Regulations: Adhering to quality control standards ensures compliance with industry regulations, avoiding potential legal and financial repercussions.

Overview of CNC Machine Quality Control

CNC machine quality control encompasses a comprehensive inspection process from the initial raw material inspection to the final product testing. Here’s a brief overview of the key stages involved:

Raw Material Inspection: The first step in the quality control process is ensuring that the raw materials meet the required specifications. This involves verifying the material’s composition, properties, and compliance with industry standards.

In-Process Inspection: During the machining process, dimensions, tolerances, and surface finish are continuously monitored to ensure that the parts are being manufactured according to the design specifications.

First Article Inspection: The initial part is thoroughly inspected to verify that it meets all design and quality requirements. This step is crucial for identifying any potential issues before full-scale production begins.

Final Inspection: Once the parts are completed, a final inspection is conducted to ensure they meet all quality standards and specifications. This includes checking dimensions, surface finish, and other critical parameters.

Statistical Process Control (SPC): SPC involves using statistical methods to monitor and control the machining process. This helps identify trends and variations, allowing timely corrective actions to maintain quality.

Documentation and Record-Keeping: Maintaining detailed records of inspections, tests, and quality control measures ensures traceability and accountability. This documentation is essential for quality management systems and compliance with industry standards.

By implementing these quality control measures, CNC machining manufacturers can ensure that their products consistently meet the highest quality standards, enhancing customer satisfaction and loyalty.

Material Certificate 3.1

Receive an authentic verification of the quality and composition of materials used to produce your parts, backed by an official test report. A single certificate validates the entire set in scenarios where all parts are crafted from the same material batch.

This certification process is meticulous. Each material batch undergoes stringent testing and analysis to ensure it meets the defined specifications and standards.

When to Use This: Material integrity is crucial for your project, and you need official documentation to verify the material specifications and compliance.

Start Your Manufacturing Project with MakerVerse

MakerVerse is your platform for sourcing industrial parts, providing instant access to a vetted supply chain and a full range of manufacturing technologies. With AI-powered quoting, order management, and fulfillment, MakerVerse helps with everything from initial prototypes to full-scale production.

Dimensional Measurement Report

Ensure every detail of your CNC machined parts is up to spec with a Dimensional Measurement Report. This document provides a record of measurements and dimensions for select sample parts from your order, confirming they adhere to the specified tolerances.

Precise instruments capture the intricate details of your parts, measuring dimensions to ensure conformity. Whether it’s a complex geometry or critical dimensions, this report provides the data you need to verify that every aspect of your part meets the stringent standards required for your application.

When to Use This: This is ideal for projects where adherence to specified dimensions is paramount and a detailed report is required for quality assurance.

Certificate of Conformity

Obtain peace of mind with an official Certificate of Conformity, a formal declaration that attests to your parts’ compliance with all provided requirements and specifications.

Regardless of the complexity or simplicity of your parts, the Certificate of Conformity is a stamp of approval, ensuring that every component in your order has undergone rigorous inspection and quality control procedures. Only one certificate is necessary per order, simplifying the validation process.

When to Use This: Whenever you need formal assurance that your parts have been manufactured to meet all specified requirements and standards.

Certificate of Origin

This certification is crucial for customs and trade, ensuring transparency and compliance with international trade regulations.

Whether for tariff considerations, trade agreements, or just for your records, the Certificate of Origin provides a clear and official declaration of where your parts were manufactured. This transparency is vital in today’s global manufacturing landscape, ensuring that every step of the production process is accounted for.

When to Use This: This is particularly important for international shipments and trade compliance or when the origin of the parts is a critical factor for your project.

Optical Dimensional Measurement (3D Scan)

With this option, you can compare the part’s dimensional properties to the original design. By default, the best-fit method for alignment will be used, but if necessary, your report can be adjusted to a defined reference point.

Dimensional measurements are conducted with a ZEISS Gom ATOS 12 m or similar device. First, moving fringe patterns are projected onto the part’s surface with a high-power blue light source. High-quality stereo cameras capable of high resolutions capture the reflections from the projection. Ambient non-blue light is filtered out to measure the dimensions of the printed part. When choosing a 3D scan, you’ll receive an inspection report providing false-colour pictures from three angles.

When to Use This: When free-form structures or contours need to be quickly measured for accuracy

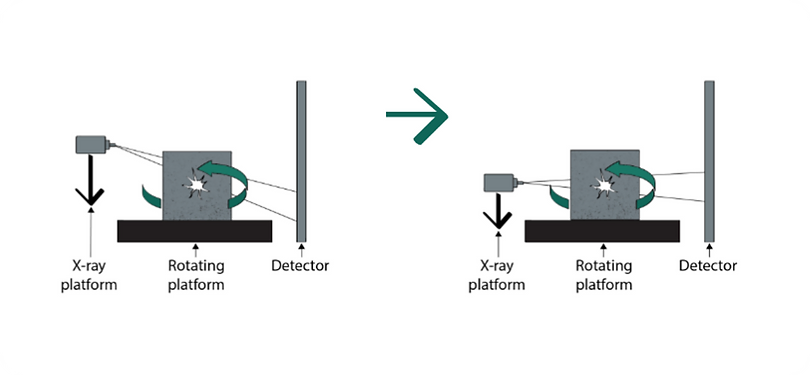

CT Scan

A CT (computed tomography) scan provides a detailed look at the part’s internal material properties. The part is placed between an X-ray emitter and an X-ray detector for the CT scan. A tomographic reconstruction is made by emitting X-ray beams from different angles for various layers. This process provides a detailed cross-section view of the part in virtual slices.

A CT (computed tomography) scan provides a detailed look at the part’s internal material properties. The part is placed between an X-ray emitter and an X-ray detector for the CT scan. A tomographic reconstruction is made by emitting X-ray beams from different angles for various layers. This process provides a detailed cross-section view of the part in virtual slices.

This scan is performed according to ISO 17025 standards, which “enables laboratories to demonstrate that they operate competently and generate valid results.” This option includes the CT data for self-analysis (GOM Volume Inspect) and an expert report for an additional charge.

When to Use This: When checking the internal material properties of a metal part against potential defects, errors, pores, inclusions, or voids.

Surface Roughness Measurement

A part’s surface roughness can affect its durability, friction, and other factors, so it is essential for industrial use to get the roughness within an acceptable range.

A part’s surface roughness can affect its durability, friction, and other factors, so it is essential for industrial use to get the roughness within an acceptable range.

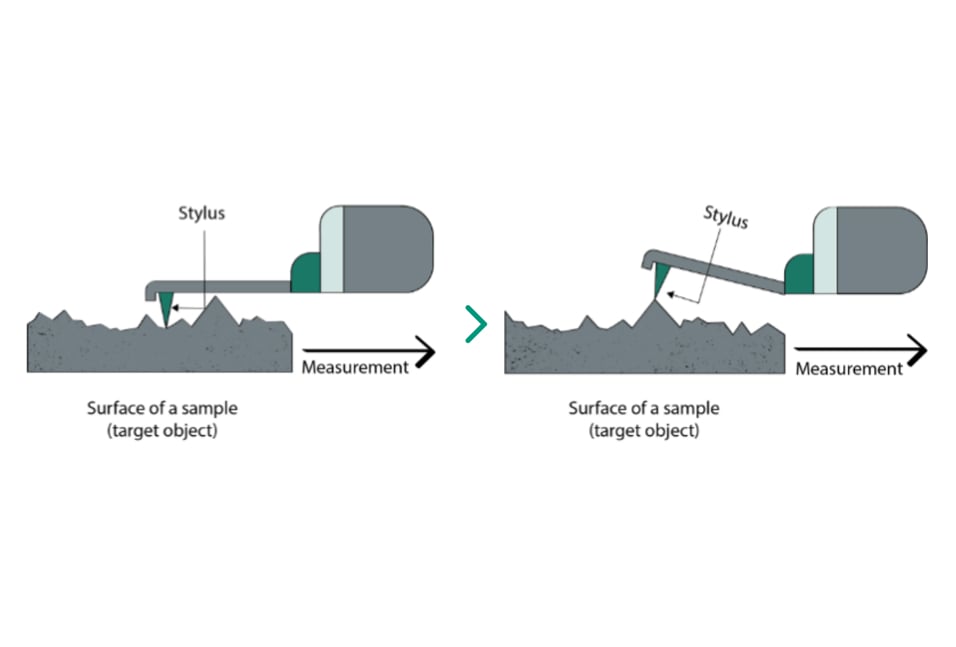

A sensitive stylus is dragged along the surface, measuring the heights and valleys with a precision better than .03μm. The measurements are extrapolated to the entire surface, computing roughness metrics. This process is all performed according to the DIN ISO 4287 standard. You will receive a report with your part, including the heights and valleys from the path up to 50mm and the computed Rz and Ra values.

When to Use This: When the surface roughness is critical to the function of the part.

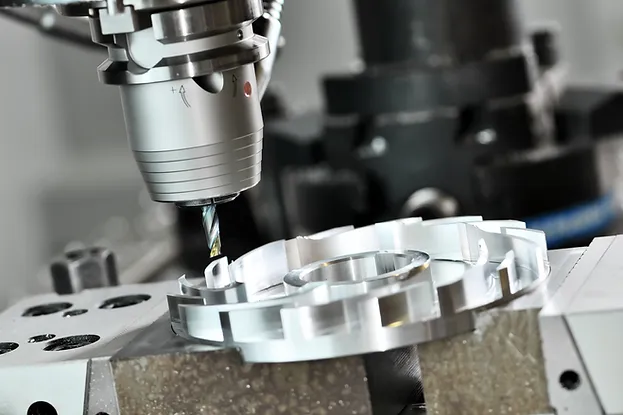

High-Quality CNC Machining Services

At MakerVerse, we provide industrial-quality CNC machining services. To get an instant quote, upload your 3D file and 2D technical drawing.